Products

1.Lean Six Sigma Green Belt Certification

3 Days In-Person, Hands-on Program

Program Overview:

Today's leaders in organizations must deliver high-quality services and products while managing limited staff and budgets. The Lean Six Sigma Greenbelt Certification Course equips learners with essential tools to eliminate waste and balance quality with cost. This program covers the fundamentals of Lean Principles alongside Six Sigma, a customer-focused, data-driven process improvement methodology.

Participants will analyze and address quality issues through practical improvement projects, demonstrating their understanding of the Six Sigma tools presented. By effectively applying Lean and Six Sigma methodologies, participants will earn their Lean Six Sigma Green Belt Certification. This will help in their journey towards Lean Six Sigma Black Belt.

Learning Objectives:

By the end of the course, the participants will be able to:

- Define lean tools, principles, concepts, and methodologies.

- Demonstrate use of Six Sigma project tracking tools to improve quality issues & sustainability.

- Apply the concept of “Test of Change” and see positive results (ROI).

- Lead and participate in Lean Six Sigma projects.

- Learn tools like VSM, 5S, 8WASTE, TAKT Time/Cycle & Lead Time, Multiple Graphs for Data presentation, Pareto Charts, Single Piece Flow, Cell Design, Load Balance KPI/Metrics

2.Lean Six Sigma Black Belt Certification

3 Days In-Person, Hands-on Program

Program Overview:

In today’s post-COVID-19 landscape, organizations must optimize operations to enhance efficiency. This involves minimizing non-value-added activities while amplifying those that directly contribute to value. Such improvements not only elevate customers' safety but also lead to stronger financial outcomes.

A Lean Six Sigma Black Belt equips Green Belts to design and implement more effective processes through data-driven decisions instead of instinctual choices. Green Belts who have successfully initiated and completed at least one project will build on this foundation, gaining deeper expertise to lead initiatives that reduce process variation and drive measurable improvements.

Learning Objectives:

By the end of the course, the participants will be able to:

- Demonstrate the ability to lead a project independently.

- Teach the tools, techniques, and methodologies of Lean Six Sigma to a project team.

Pre-Requisites to Registration:

Before being permitted to register, the following must be submitted:

- Submit proof of your Green Belt Certification along with the specified project details below.

- Project Charter

- Show Baseline Data, Benchmark or Target Data, Outcome, and Process Metrics

- Show a Bar or line graph with baseline data and the last three months' data to illustrate progress with a trend line. Also, draw the target line.

- Process Maps - Current and Future

- Gap Analysis – identify gaps and probable solution(s)

- Test of Changes / Pilot Runs in Bar Graphs / Line Graphs

- Implementation Plan

- Communication Plan

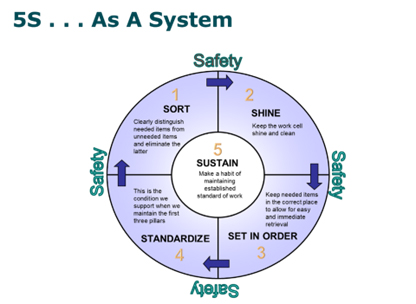

3. Lean Six Sigma fundamental tool: 5S

"Everything has a place and Everything in its place." This is the foundation of 5S, a workplace organization methodology also known as the 30-second rule. Things should be available within 30 seconds, whether you are looking for a document, tool, file, product, etc.

After implementing 5S in hundreds of organizations over 25 years, we've optimized the sequence by swapping Shine with Set-in-Order. We've found it more effective to clean first before putting things back in order.

Original Sequence

- Sort

- Set-In-Order

- Shine

- Standardize

- Sustain

Preferred Sequence

- Sort

- Shine

- Set-in Order

- Standardize

- Sustain

| English | Japanese |

|---|---|

| Sort - | (Seiri) |

| Shine - | (Seiso) |

| Set in Order - | (Seiton) |

| Standardize - | (Seiketsu) |

| Sustain - | (Shitsuke) |

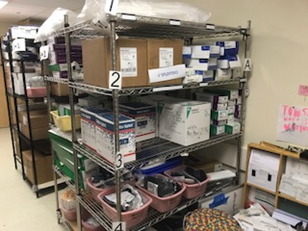

Before 5S Implementation

After 5S Implementation

ED Supply room before 5S

ED Supply room after 5S

4. Lean Six Sigma Tool: KAIZEN Event (KE)

Another very powerful tool in Lean Six Sigma is the KAIZEN Event. The KE focuses on solving a particular problem that is hindering in moving the process improvement forward. You can do multiple KE on a process till the roadblock is eliminated.

The KAIZEN Event can be from 1/2 day to 5 days, depending on the size of the issue. I have facilitated close to 100 Kaizen Events of different durations with a success rate of 99.5%. My measurement of success is the sustainability of implementation.

A small team of about 5 to 6 key decision makers is gathered in a room with the Executive Sponsor and the Process Owner. The Project Charter is initiated with the baseline data and the target/goal with a S.M.A.R.T objective. It is a lot of fun because some of the actions get implemented with no time wasted, which has taken months in weekly meetings.

- "Change for the Better" - The core meaning of Kaizen

- Continuous improvement through waste elimination

- Involving key stakeholders

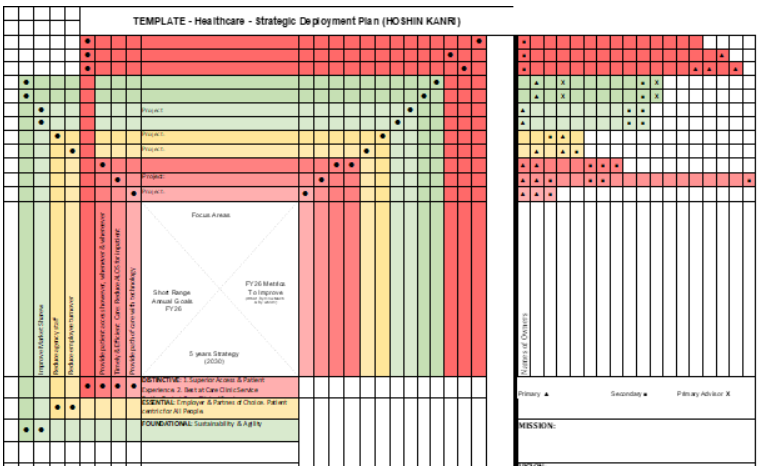

5. Lean Six Sigma tool: Hoshin Kanri / Strategy Deployment.

This tool is used for Strategy Deployment before the new fiscal year starts to identify the next 5-year plan and which vital few actions to be executed in the coming year to move closer to the 5-year plan. I have facilitated a few of these with great success. The success comes from selecting the Vital Few items, which can be done in a year, and not trying to boil the ocean, with a truckload of projects, and nothing gets done in a year. Organizations end up with half-cooked potatoes.

8 to 10 key leaders are gathered off-site for about 3 days and facilitated by me with a template as shown in the picture. At the end of the session, the teams have a solid road map with action items, ownership, and metrics established.